Jordan

Pennington

ARCH 653

Project 1: Shipping and Transport College, Neutelings Riedijk Architecten

Rotterdam,

the Netherlands, 2005

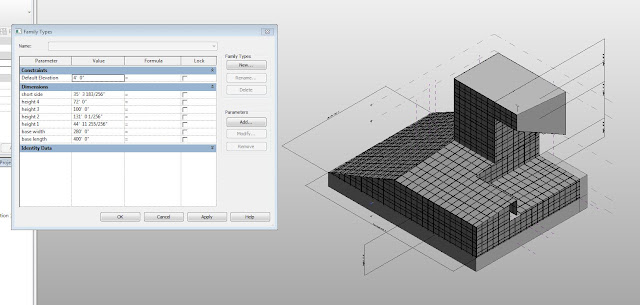

Model

Description

The mass model was made in Revit using the

“Create Form” function in a conceptual mass template. The form is made of three

different solid forms and one void form. Together, these make the rectangular

base, the tower, and a protruding volume at the top of the tower. After

creating the different forms, I edited individual faces of the forms by moving

their edges and points to create the different angular faces of the building.

Dimension parameters keep the geometry of the different solids working together

if the mass of the model changes.

Parametric

Building Envelope

Next, the parametric building envelope was

created by altering the “Rectangle Surface” curtain panel family. A system

of gray and white corrugated metal panels create a checkered pattern with

strips of glazing in between. To create this system, the original rectangular

panel was edited to the proper dimensions and then divided into 8 individual

panels (4 metal rectangles and 4 glazing rectangles). A surface form was then

created for each of these individual panels (after setting a rectangular sweep

was created along the edge of these boundaries). This allowed each of the

individual panels to have a material parameter (gray metal, white metal, glass) that

could be defined once loaded into the project.

Parametric

Building Envelope, Panel 2

A second, similar panel system was created in the same way for the

surfaces of the building that have the same gray and white checkered pattern,

but do not have glazing.

The surfaces of the conceptual mass were divided with vertical and

horizontal grids that were set by distances that corresponded to the dimensions

of the parametric panel. The two curtain panel systems were then loaded into the

proper surfaces of the conceptual mass model. Once the panels were loaded to

create a custom curtain panel system, there were some issues with the original

location of the systems. Some needed to be offset vertically or horizontally.

Surfaces of the mass that had edges at angles other than 90˚ required the

curtain panel system to be rotated.

Once the massing model was loaded into the project file, the different

materials could be assigned to the new material parameters of the curtain panel

systems.

Finishing

the Massing

Once the conceptual mass was loaded into the project file, floors, roofs, and walls were massed by face. Other exterior details

were added such as curtain walls and a site, which is located on a dock along the coast of the

North Sea.

Sample

Floor Plan

The floor plan and reflected ceiling plan of level 9 were modeled to

illustrate how the majority of the building, the tower, is used. It consists

mainly of classrooms and offices and features a series of escalators at the

core of the tower.

Renderings

and Screen Shots

Original mass modeling with parameters

applied to resemble actual building

Mass with dimensions parameters flexed

Project with panel material parameters changed

Project with panel frame parameters flexed